Precision Vacuum Casting Services

High-fidelity urethane casting for rapid prototyping and low-volume production. Get production-quality parts in as fast as 5 days.

High-fidelity urethane casting for rapid prototyping and low-volume production. Get production-quality parts in as fast as 5 days.

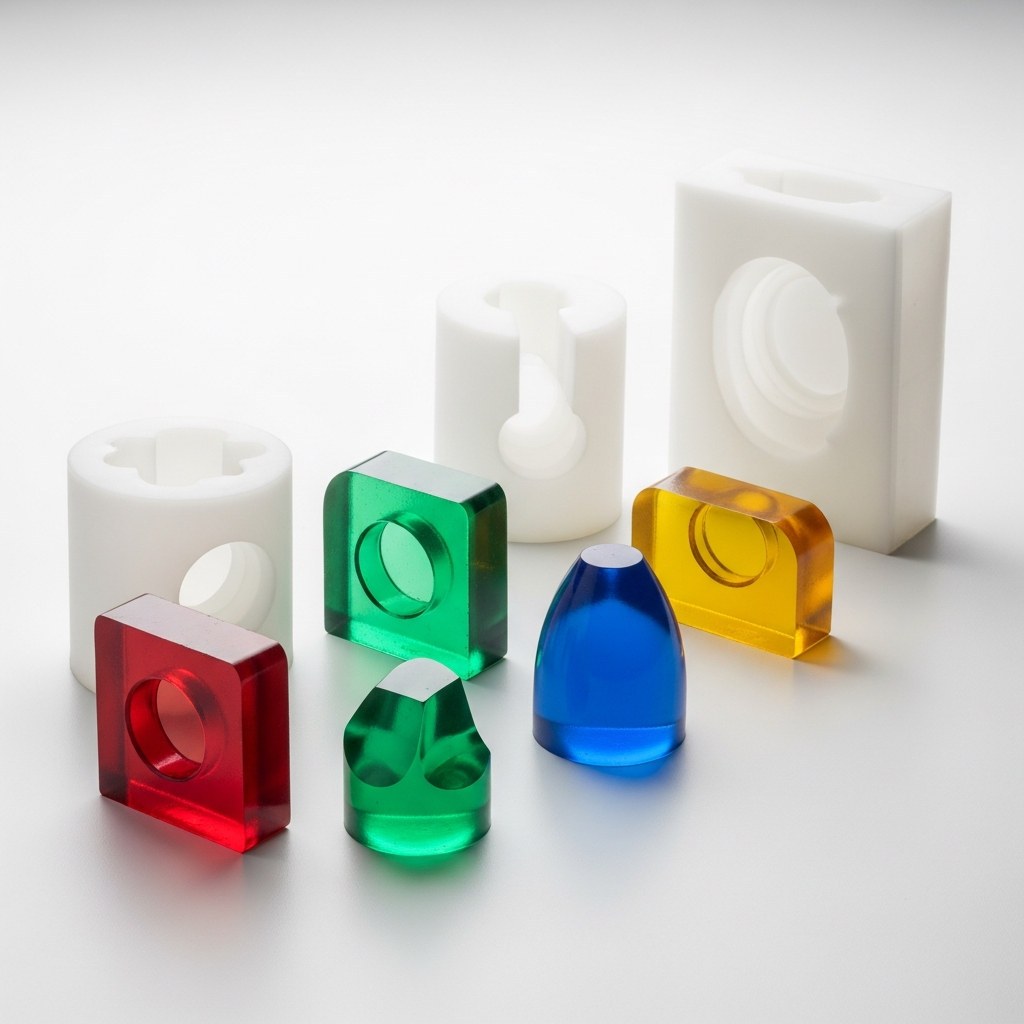

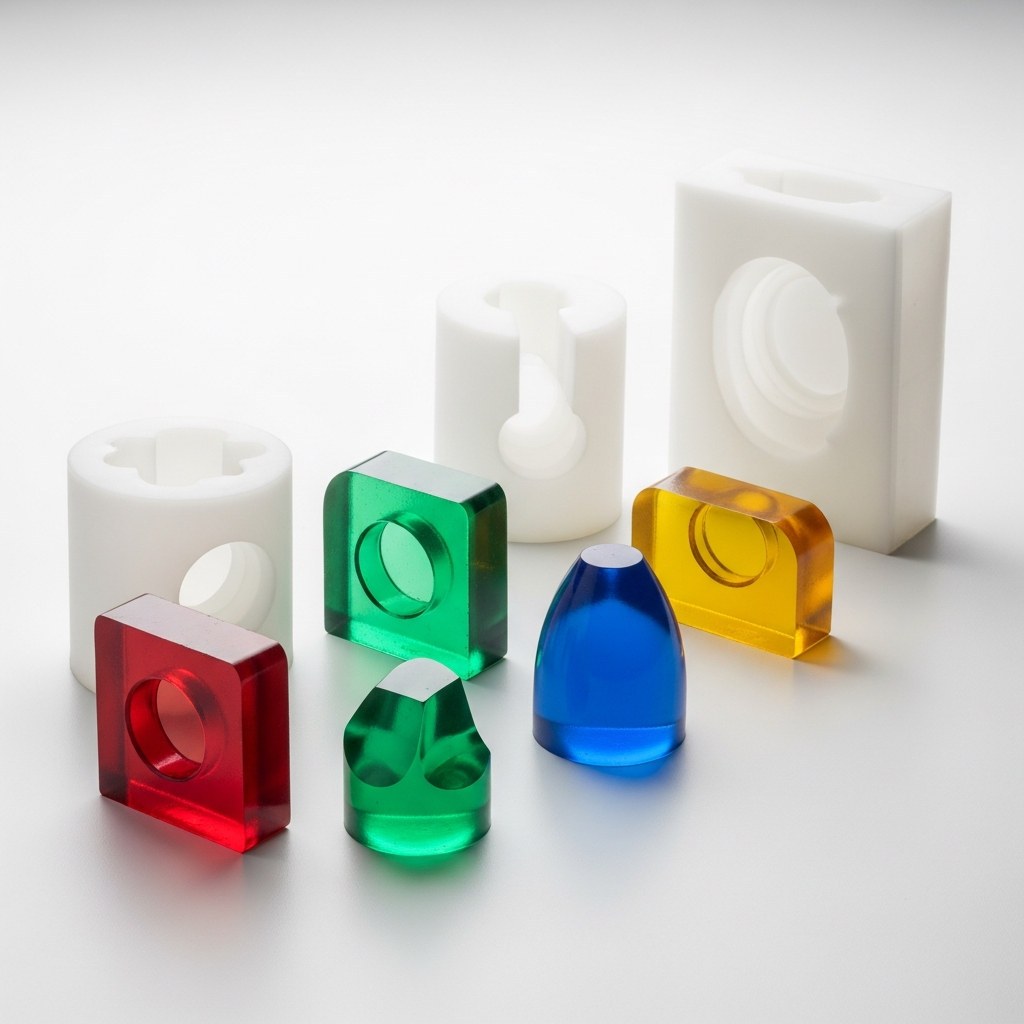

Our vacuum casting process is engineered for high-fidelity reproduction of complex geometries. By utilizing medical-grade silicone for our molds, we capture sub-micron surface details that traditional machining often misses. This makes Metasource the preferred choice for industrial designers requiring aesthetic perfection and functional precision.

Vacuum casting serves as the ultimate bridge between rapid prototyping and full-scale injection molding. We utilize a diverse range of polyurethane resins that simulate the mechanical properties of production plastics like ABS, Polypropylene, and Polycarbonate, allowing for comprehensive functional testing before committing to expensive tooling.

“Metasource transforms digital designs into tangible reality with a focus on speed, quality, and material integrity. Whether it's a single functional prototype or a small batch for market validation, our expert technicians ensure every part meets ISO 9001:2015 standards.”

From master pattern to final part, our process ensures high fidelity reproduction.

A master model is created using high-resolution 3D printing (SLA) or CNC machining to ensure perfect surface finish and dimensions.

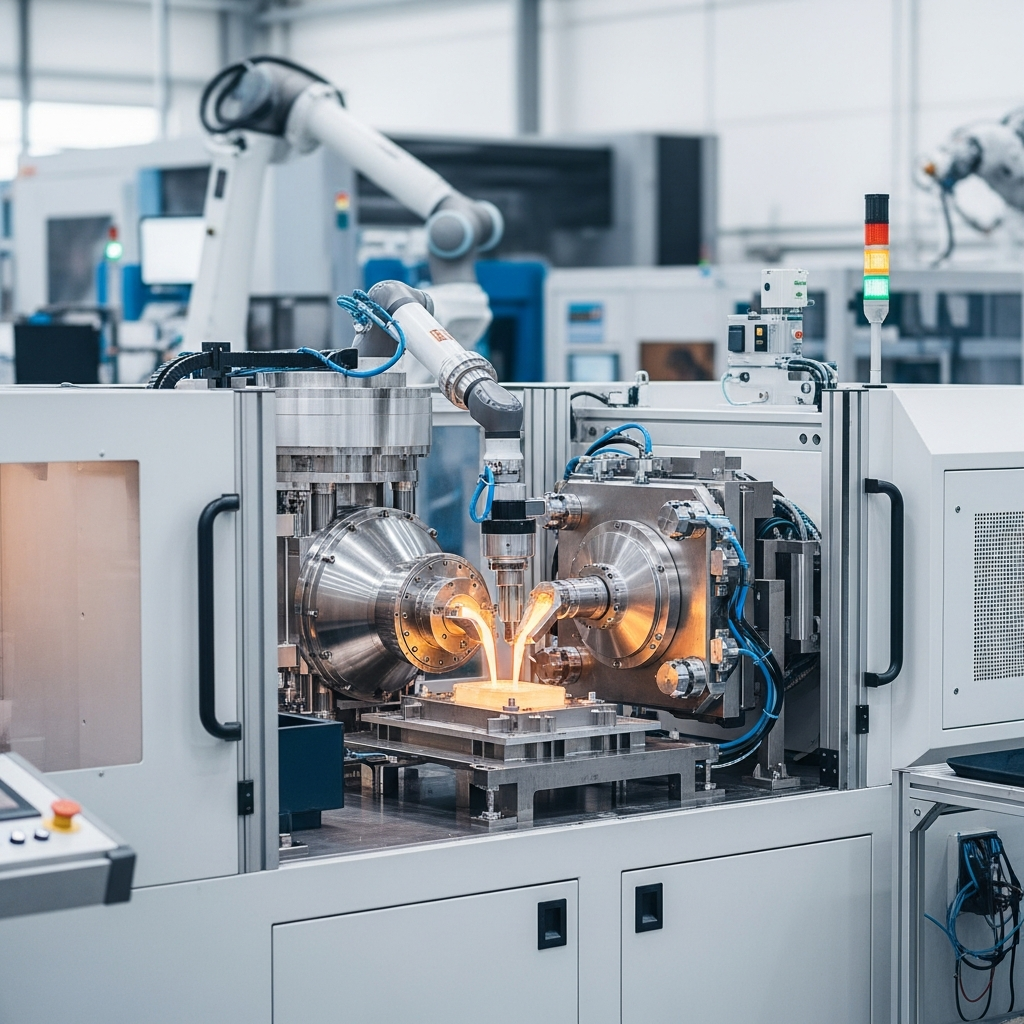

Liquid silicone is poured around the master pattern in a vacuum chamber to create a defect-free mold cavity.

Polyurethane resin is injected into the silicone mold under vacuum, replicating every detail of the original design.

Access a wide range of resins simulating ABS, PP, PC, and rubber.

Create parts with undercuts and complex details that are hard to machine.

Custom textures, polishing, painting, and branding options available.

Ideal for functional testing and pre-launch marketing samples.

We offer a comprehensive library of polyurethane resins to match your specific engineering requirements.

High impact strength, excellent thermal resistance. Great for functional snap-fit parts.

Flexible and tough. Resistant to fatigue. Ideal for clips and living hinges.

Optical clarity comparable to PMMA/PC. Perfect for lenses and light guides.

Variable shore hardness (Shore A 30–90). Used for gaskets, seals, and overmolds.

Just 4 simple steps to get your manufacturing projects moving.

Upload your inquiry with material grade, size, and quantity on the MetaSource platform.

View multiple price options from trusted suppliers—compare rates, lead times & certifications.

Select the best deal, confirm your order, and complete payment.

Get your materials & projects delivered fast, with quality guaranteed anywhere in India.