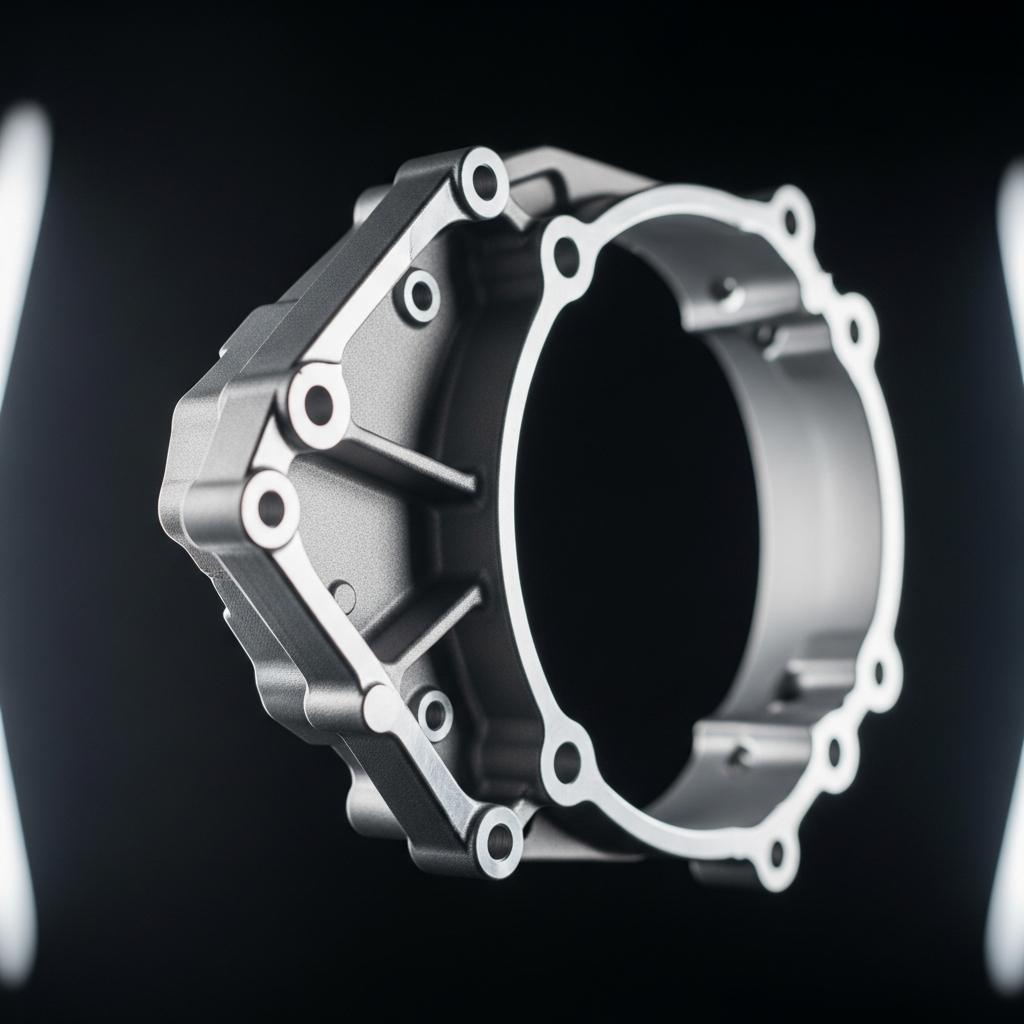

CUSTOM DIE

CASTING SERVICES

From prototypes to high-volume production runs, RapidDirect’s die casting services have you covered. We work with aluminum, zinc, and magnesium, and handle everything from tooling to finishing.